CO2 Regulator

Recently, due to the sharp price increase of domestic CO2 gas, the welding costs of various manufacturers have increased a lot.

The gas restrictor made in Japan (Chiyoda Seiki) is used to reduce the production cost for the customer, and the saving rate can vary from 20% to 40% according to the welding process of the customer.

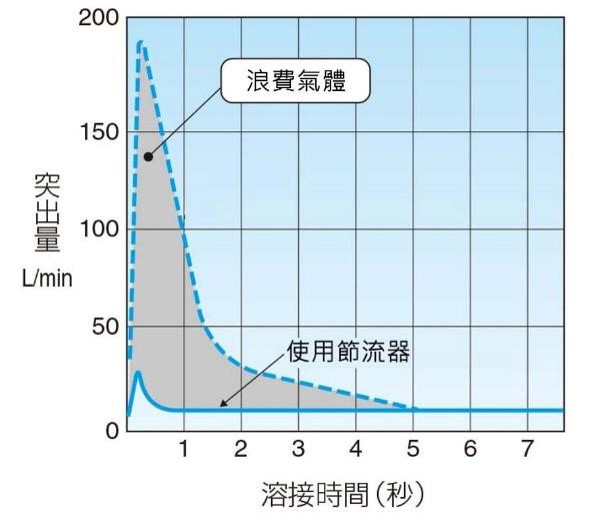

At the moment when welding starts, a large amount of wasted gas will be generated due to the pressure. (see image below: dotted line)

If you use a restrictor, you will find that it becomes like the solid line in the picture below, and you can save a lot of shielding gas.

In addition to the gas saving function, the welding gas restrictor also has the function of a dial-type flowmeter. Compared with the general float-type flowmeter, it is less affected by the length of the external gas pipeline and can accurately output the adjusted flow rate.

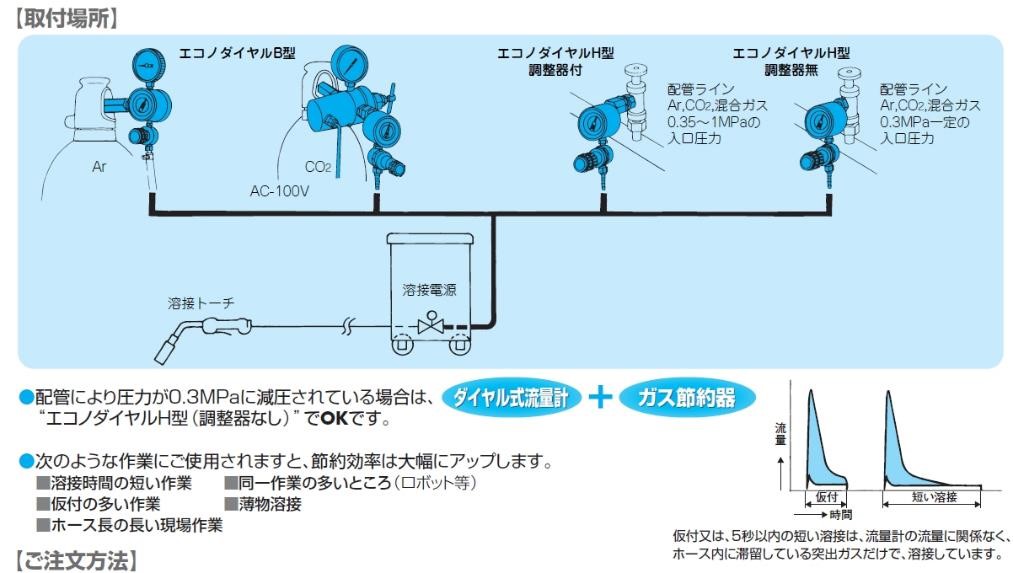

Whether the gas restrictor is used on a steel cylinder or a unified delivery pipeline, it can achieve the effect of gas saving through its unique function (3KG/10KG style is required),

It is easy to install and use, and has a wide range of applications. It can be used regardless of equipment such as automatic robot welding or hand welding machines.

Applicable gases such as carbon dioxide, mixed gas, argon and other commonly used welding gases are all acceptable.

At a time when gas prices are skyrocketing, minimize gas waste with a gas restrictor!

It maintains a stable gas flow from the beginning of welding without affecting the welding quality, and realizes energy saving and smooth arc start.